Menu

OUR

PRODUCTS

- Home

- Products

- Integral Line System

- SM-2101-2PF2S

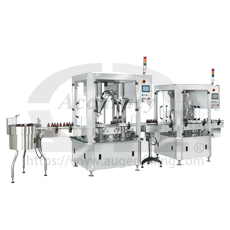

SM-2101-2PF2SAutomatic Double-head Filling Plugging Machine

- Designed for automatically metering, filling powder and granular products into sectional bottle with plug insertion function.

- Range of filling and metering: 0.3-5 g.

|

|

Product Feature

- SM-2101-2PF2S Automatic Double-head Filling Plugging Machine is designed for filling micro powder or granular into vials with plug insertion automatically with great accuracy, such as herbal powder, powdered medicine, seasoning powder, chemical powder etc.

- It is suitable for metering and filling a wide range of free flow or non-free flow powdered products.

- It can reach the weight range from 0.1~5 g by simply changing auger shafts without any tools.

- Auger shaft is made of stainless steel, and based on one-piece integral processing to ensure the accurate of measurement. Metering tolerance is within ±3~5%.

- All material contact parts are made of stainless steel (Standard type 304 / Optional type 316).

- Using intermittent double-head auger filling system to operate with vials delivered into accurate positions on a circular, multi-position turret as well as accomplished filling and plug insertion. All vials are transported through integral infeed and output conveyors.

- With self- diagnostic device, intermittent auger filling system is able to stop operations automatically while any error occurs. Meanwhile, it will trigger alarm and show the event on HMI touch screen.

- With bottle detection device, it is able to stop filling while there has no bottle. It also can stop operation while bottle jammed occurs.

- HMI touch screen for operational control. It has 10 sets of memory modules for memorizing different kinds of products and filling weights. Simply enter the code number to change production modules.

- Customized design and fabrication of the production line system is available.

Product Specification

| Model | SM-2101-2PF2S |

|---|---|

| Machine Size | L: 1500 × W: 1350 × H: 1950 mm |

| Machine Weight | 850kg |

| Packaging Speed | 30~40 bottles /min(Vary with different products,and filling weight) |

| Power Required | 220V,3Ø,5.0HP,50/60Hz |

| Air Pressure | 4-5 kg/cm2 |

Product Video

INQUIRY

INQUIRY  WATCH VIDEO

WATCH VIDEO